We can help make our company more profitable by preventing unnecessary costs from hitting Publix’s bottom line, and as company owners, that benefits us all. Associates are our first line of defense to avoid excess maintenance charges.

Equipment

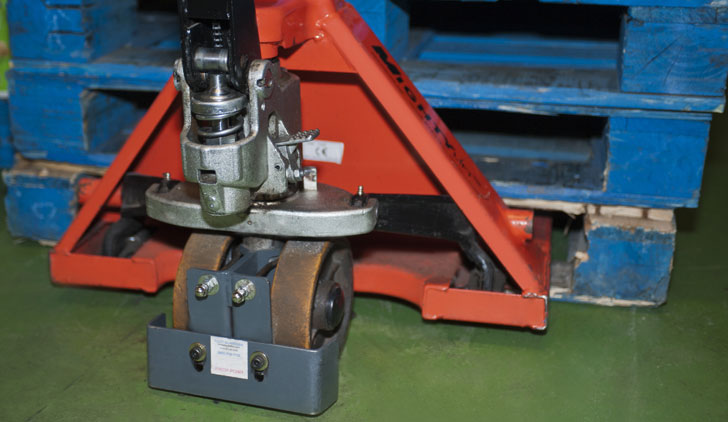

Pallet jacks should not be stored in coolers or freezers because hydraulic fluid does not work properly after being exposed to cold temperatures. So, it’s important to store pallet jacks at room temperature to keep them working properly.

Grease buildup from deli fryers can damage equipment if it accumulates around knobs and controls. Clean those areas often and replace the fryer filter as indicated in the Deli R&P Guide.

Electric plugs

One of the most common reasons plugs stop working is from tugging on the cord rather than gently pulling the plug out of the wall. Sometimes the location of the plug makes it difficult to remove, but a service call to facility services can easily remedy the problem. A common request is to move plugs after relocating equipment and prep tables, receiving new equipment and during or after a remodel.

Parts

After taking apart and cleaning equipment, prevent small pieces from being misplaced by making room on the drying rack to store the parts together while they dry. Always make sure parts are fully dry before reassembling.

The No. 1 Steritech violation our stores receive is for gaskets being dirty, ripped, damaged, cracked, loose or misplaced. Prevent violations and increase the life of parts and equipment by making sure gaskets are clean and in good condition, as indicated in your department’s R&P guide.

Chemicals

Only use approved chemicals when operating the floor scrubber. Using the wrong chemicals can not only damage the equipment but also our floors.

Block whitener should only be used in the meat, produce, deli and bakery departments to whiten cutting blocks. The full list of approved chemicals and uses is available on Publix Connection > Store > Food Safety > References and Questions > Sanitation.

Plumbing

Sweeping or mopping solid items or grease down floor drains can cause plumbing issues. Always dispose of trash and grease correctly to prevent excess service calls.

Grease barrel

Properly dispose of grease by pouring it into the grease barrel. Use caution while transporting it to avoid spillage since grease damages our flooring and asphalt.

Service calls

Notify your manager immediately if something needs to be repaired. When problems are reported early, they tend to cost less and take less time to repair. Managers can report issues to the facility services contact center by calling 1-888-322-5454 and selecting option one.